OUR BUSINESS 02

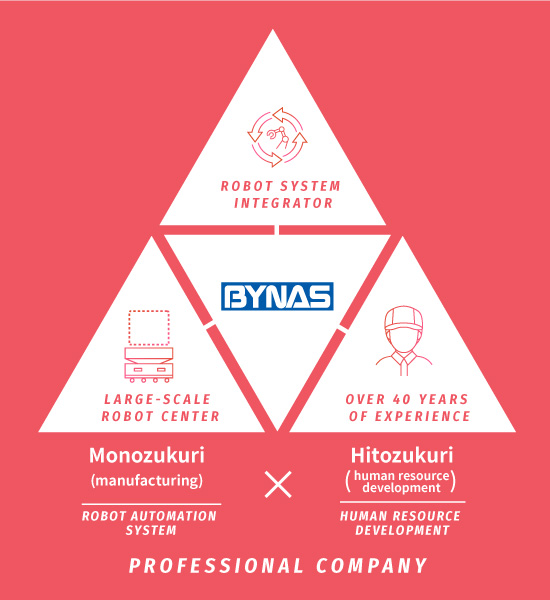

FA ROBOT SOLUTIONS- Home

- About

Us - Corporate

Information- Corporate Information List

- OVERVIEW & HISTORY

- GREETING & PHILOSOPHY

- BUSINESS OFFICES

CORPORATE INFORMATION

- Investor Relations

(jump to Japanese site) - Our

Business - Sustainability

- CDS

Group - CONTACT

- General InquiriesContact us here for inquiries regarding CDS, and for catalog requests, etc.

- Inquiries Regarding Investor Relations InformationContact us here for inquiries regarding investor information

CONTACT US